1000W 1500W 2000W 3000W 3 in 1 Laser Welder Portable Handheld Fiber Laser Welding Machine for Stainless Steel Aluminum Alloy Products

Overview Laser welding is a new type of welding method and one of the important aspects of the application of laser mate;

Basic Info

| Model NO. | ST-1500W |

| After-sales Service | 24 Hours Online Support |

| Warranty | 3 Years Warranty |

| Application | Biomedicine, Electronic Industry, Automotive Industry, Powder Metallurgy, Manufacturing Industry |

| Technical Class | Continuous Wave Laser |

| Control | Automatic |

| Power Density | Heat Conduct Welding |

| Laser Classification | Optical Fiber Laser |

| Type | Optical Fiber Transmission Laser Welding Machine |

| Produce Name | Fiber Laser Welding Machine |

| Laser Power | 1000W/1500W/2000W/3000W |

| Laser Source | Raycus(Optional Jpt or Ipg) |

| Laser Wave Length | 1080nm |

| Fiber Cable Length | 10 Meters |

| Welding Speed | 0-120 mm/S |

| Water Cooling | Industrial Water Chiller |

| Laser Head | Relfar Qilin |

| Controller | Relfar Qilin |

| Spot Size (mm) | 0.2-5mm Adjustable |

| Auto Wire Feeder Device | Yes |

| Functions | Welding Cutting Cleaning |

| Cleaning Width | 10-80mm |

| Handheld Laser Welding Machine | Fiber Laser Welding |

| Laser Welding | Laser Welding Equipment |

| Transport Package | Free-Fumigation Wooden Box |

| Specification | 1620*700*1450mm |

| Trademark | Jnstar Laser |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 800 Sets/Month |

Product Description

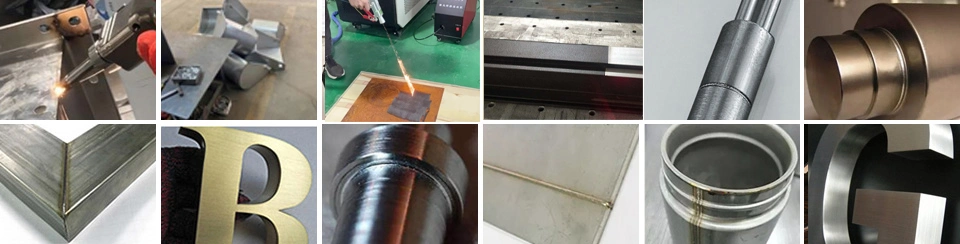

Laser welding is a new type of welding method and one of the important aspects of the application of laser material processing technology. Laser welding is mainly for the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small welding width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful welding appearance, no need to handle or just need simple processing after welding, high welding quality, no air holes, precise control, small focus spot, high positioning accuracy.Features1. High quality fiber laser beam, high conversion efficiency and therefore high welding speed, high aspect ratio, high strength.

2. High laser energy density, small thermal effect area, not easy deformation, less or no subsequent processing.

3. Top brand gold cavity, high temperature resistance, corrosion resistance, the service life is 8 to10 years, the xenon lamp service life is more than 800 million times

4. Non-contact processing, stress free, noiseless, no pollution to the environment, which belongs to the green processing.

5. Good welding quality, smooth and beautiful appearance.

6. Touch screen input, friendly human-computer interaction makes setup and operation easier. The operating system is easy to learn and easy to operate.

7. Solder joints non-pollution, weld strength and toughness at least equivalent to or stronger than the base metal.

8. A variety of input and output signals are very easy to achieve the machine's automated production and assembly line production.

Detailed PhotosHandheld welding headLight shape, economic deign, it offers so much welding convenience for welding. Intelligent single pendulum handheld welding head, the swinging width can be set maximum 5mm. Welding + cleaning + cutting 3 function, Three-in-one. Fiber Laser sourceAdopting famous brands Raycus ( optional JPT, Max or IPG) the photoelectric conversion rate is greatly improved, laser power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet customer needs. Industrial Water chillerOne of the biggest convenience of the machine is the inside water chiller. It saves a lot of the machine's dimension.It is constant temperature industrial type. Touch ScreenEasy to operate, interactive control system expand the tolerance range and welding width of the processing parts, have processing library for different metal material and thickness. Auto Wire Feeder DeviceIf gap is more than 0.5mm, wire feeder device must be selected. If gap is 0.6mm, you can use 0.8mm wire. If gap is 0.8mm, you can use 1.0mm wire. If gap is 1.0mm, you can use 1.2mm wire etc. Welding Nozzle and Cutting NozzleWelding Nozeel 0.8, 1.0, 1.2, 1.6 for inner corner welding, support welding wire. Cutting Nozeele for cutting

Product Parameters

| Machine Name | Handheld Fiber Laser Welding Machine |

| Model | ST-FL1000W, ST-FL1500W, ST-FL2000W, ST-FL3000W |

| Laser Power | 1KW, 1.5KW, 2KW, 3KW |

| Laser Wave Length | 1080nm |

| Laser Source | Raycus(optional JPT or IPG) |

| Operate mode | Continuation/ modulate |

| Welding speed | 0-120 mm/s |

| Fiber Cable Length | 10 Meters |

| Cooling Mode | Water cooling(Industrial water chiller) |

| Laser Head and Controller | Relfar / Qilin |

| Laser Pulse Frequency | 1-20HZ |

| Laser Pulse Width | 0.1-20ms |

| Spot Size (mm) | 0.2-5mm Adjustable |

| Welding gap requirements | ≤0.5mm |

| Gas source | 0.2Mpa (Argon) |

| Positioning | Red Dot Positioning |

| Functions | Welding Cutting Cleaning |

| Cleaning Width | 10-80mm |

| Working Voltage | (1kw 1.5kw 2kw) AC220V, 50/60HZ, Single Phase (3kw) AC380V, 50/60HZ, Three Phase |

| Working temperature | 10-40ºC |

| Power consumption | 8KW |

| Package Size | 162CM L *70CM W*144CM H |

| Gross Weight | 320KG |

There are 3 layers of package: 1. waterproof thickening plastic bag, 2. foam to protect from shaking, 3. export standard free-fumigation wooden box.

CertificationsCompany ProfileJinan Star Machinery Equipment was located in Jinan city, Shandong province, China. Jinan Star Machinery Equipment is the leading manufacturer of quality industrial laser & CNC equipments. We are committed to provide high quality products by constant innovation, research and development to meet the needs of our customers.Jinan Star Machinery Equipment is a high-tech modern enterprise integrating with manufacturing, marketing, servicing, research and development. We manufacture a full range of laser and CNC machines, like fiber laser cutting machine, fiber laser marking machine, fiber laser welding machine, oscillating knife cutting machine, plasma cutting machine, CO2 laser engraving machine, CNC router and etc. We are committed to providing high quality products, competitive prices and excellent services for customers from all over the world, and looking for worldwide reliable distributors.

FAQQ: How about the delivery time, package and delivery?

A1. Standard model 7 - 10 working days after receiving the down payment.

2. There are 3 layers of package: waterproof thickening plastic bag, foam to protect from shaking, free-fumigation export standard wooden box.

3. Shipping by UPS/DHL/Fedex express, airline delivery to airport or by Sea.

Q: How about the warranty and after-sales service?

A1. We provide two year warranty for whole machine and lifetime maintenance.

2. 18 hours technical support by email, calling, Weechat, Whatsapp or remote assistance(TeamViewer or AnyDesk).

3. Lifelong free training for operation.

You may also like

Send inquiry

Send now